Safety is Our Priority

Nothing is more important than safety. Our philosophy is that if it cannot be done safely, it should not be done at all.

Safety Training

Submar provides continuous safety training to all our employees through the International Association for Continuing Education and Training (IACET) certified online safety training platform, called SafetySkills. We train our employees on over 50 safety topics throughout the year, and courses are assigned quarterly. Using a third-party provider ensures that Submar employees have the most up-to-date training available, offers the ability to monitor and track training completion, and it enables a pre-defined retraining schedule to be established.

Operator Qualification

Submar’s safety philosophy extends to our employees, who undergo extensive training. Our crews are fully qualified to work on any site, which ensures the best possible results for our clients. We are proud to be Gold Shovel Standard (GSS) Certified. The Gold Shovel Standard is a first-of-its kind excavation safety program designed to reduce dig-ins and protect the underground gas and electric system. With safety as its highest priority, the Gold Shovel Standard Certification process was developed to ensure that hired contractors are vetted annually and adhere to the safest excavation standards.

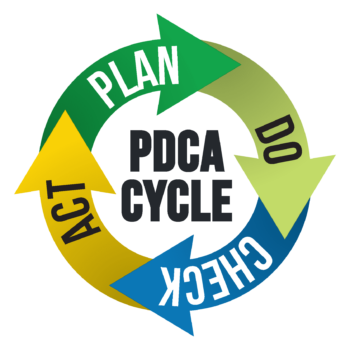

Our commitment to safety and continuous improvement is based on the PDCA Model.

Plan: Recognize an opportunity and plan a change.

Do: Test the change. Carry out a small-scale study.

Act: Take action based on what you learned in the study step.

Check: Review the test, analyze the results, and identify what you've learned.

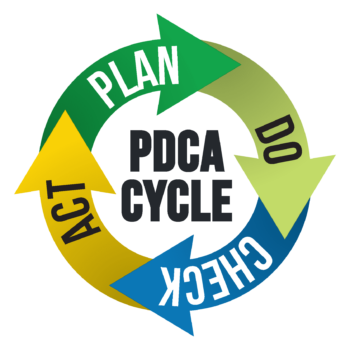

Our commitment to safety and continuous improvement is based on the PDCA Model.

Plan: Recognize an opportunity and plan a change.

Do: Test the change. Carry out a small-scale study.

Act: Take action based on what you learned in the study step.

Check: Review the test, analyze the results, and identify what you've learned.

Damage Prevention Institute (DPI)

DPI Accredited – The Damage Prevention Institute’s (DPI) mission is to build on the industry-leading insights of the Common Ground Alliance’s (CGA) Next Practices Initiative and the prior success of the Gold Shovel Association to continuously improve workforce and public safety, and the integrity of vital buried infrastructure.

AMERICAN SAFETY AND HEALTH INSTITUTE, (ASHI)

ASHI training programs are recognized, accepted and approved by, or meet the requirements of, nearly 2,400 state regulatory agencies, occupational licensing boards, national associations, commissions and councils in more than 120 occupations and professions.

ISNETWORLD

Hiring Clients request contractors to submit specific compliance and training documentation through their ISNetworld account and then evaluate the qualifications – including skills, knowledge and training – for employees coming on-site. Contractors can also better demonstrate and provide proper evidence of their employees’ training and qualifications through the tools available to them in ISNetworld.

Veriforce

The VERIFORCE mission is to deliver comprehensive, integrated, and market-driven solutions that combine innovative technology, value-added services, and unparalleled support. In doing so, we seek to be the recognized vendor-of-choice for the key solutions that organizations require to manage critical compliance programs that enhance safety and mitigate regulatory and third-party risk.

NATIONAL SAFETY COUNCIL

For 100 years, the National Safety Council has been the leading safety advocate preventing unintentional injuries and death. Contract workers often perform higher risk jobs with little management supervision. An NSC study looks at the impact of contractor management programs on contractor safety.

OQSG

We provide comprehensive Operator Qualification (OQ) solutions to help you comply with DOT 49 CFR 192 and 195 regulations. Our library of topside and underwater covered tasks contain proven methods of evaluating knowledge, skills, and abilities. Flexible options make us your perfect partner.

NCCER

Our mission is to build a safe, productive and sustainable workforce of craft professionals. Our vision is to be universally recognized by industry and government as the training, assessment, certification and career development standard for construction and maintenance craft professionals.