There are millions of miles of oil and gas pipelines in the United States—2.6 million miles to be exact, according to the Global Energy Institute of the U.S. Chamber of Commerce. Those pipelines power our daily lives and businesses. However, much of the pipeline infrastructure is old.

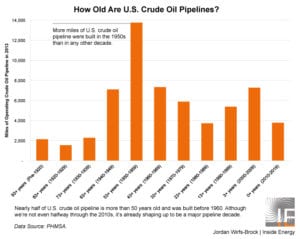

In fact, back in 2014, Inside Energy reported that 45% of U.S. crude oil pipeline is more than 50 years old—and some pipes laid in and before the 1920s are still in operation. As recently as 2017, the federal Department of Transportation (DOT) estimated 30,000 miles of cast-iron pipe still carry gas in the United States, with the highest percentage of these mains located in older eastern cities such as New York City, Philadelphia, Boston, Baltimore, and Washington, D.C.

That aging infrastructure carries risks for the community, environment, oil and gas pipeline, and transportation company’s bottom line. This means a focus on pipeline integrity must be paramount.

Replacing a Pipeline

There is an effort underway to replace this aging infrastructure. DOT data shows that replacement work, while steady, is far from complete.

In 2015, there were still 27,771 miles of wrought- and cast-iron gas distribution lines in service in the U.S., down from 39,342 miles since 2005, a decrease of almost 30%. About 97% of natural gas distribution pipelines in the U.S. were made of plastic or steel at the end of 2017, according to the DOT. DOT data showed that during the period 2004-13, distribution companies replaced 17,000 miles of bare-steel mains, leaving about 56,000 miles of bare-steel still in operation.

Maintaining Integrity

Pipeline integrity is about monitoring risk points and detection, as well as mitigating negative impacts whenever a release does happen.

Preventing releases is rooted in ensuring old or newly built pipelines are structurally and technically sound. This means ensuring lines are constructed properly, installing properly sized pumps, compressors, and suppression equipment, and investing in corrosion prevention.

Beyond pipeline construction, performing preventative maintenance and monitoring is paramount, especially for older infrastructure. There are several technologies and software tools that can help. For example, nondestructive testing (NDT) methods can detect structural damage or degradation from the outside. In addition, high-resolution in-line inspection (ILI) equipment can record data from the inside.

Finally, proper operator training is key, and even educating the people in your community can be helpful. When people are informed, they feel empowered, and problems can be avoided.

To learn how Submar can help your pipeline project bring the entire line up-to-date and maintain the integrity of the line, visit our services page.