Many solutions exist to mitigate depth of cover issues or exposed pipelines; however, some are more efficient and cost-effective than others.

Let’s compare two of the most common solutions for establishing adequate cover over pipelines: horizontal directional drilling and articulating concrete mats.

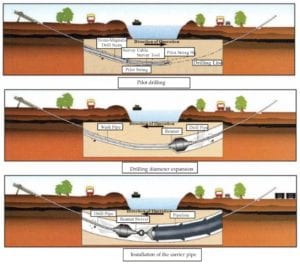

What is Horizontal Directional Drilling?

Horizontal directional drilling (HDD) is a trenchless method of pipe installation where a pipeline is installed in a directionally drilled and reamed hole using surface-mounted drilling equipment. The drilling process begins by directionally drilling a small diameter pilot hole between the entry and exit points. Upon completion of the pilot hole, the hole is enlarged to a diameter sufficient to accept the new pipeline using various diameter reaming tools. Once the hole is prepared, the new pipeline is pulled in from the exit side to the entry side.

The HDD option can be unfavorable in terms of environmental impact, and the cost can be roughly 67 times that of installing ACMs.

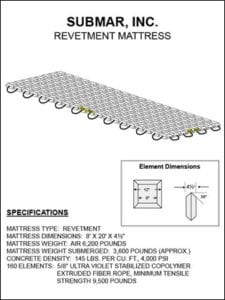

What are Articulating Concrete Mats?

Articulating concrete mats (ACMs) are a cost-effective, long-term solution. These mats, which are also used for pipeline separations and erosion control, consist of flexible concrete elements connected by ultraviolet stabilized copolymer extruded fiber rope. The mats have a low hydraulic profile in the streambed at only 4.5-inches thick and will articulate and self-adjust with the streambed to prevent the upstream migration of future head cut erosion.

Because the mattresses articulate over time and acts as a grade control structure, the hard-armor mat system will hold the current grade and prevent future degradation of the streambed. Grade control structures can provide vertical stability to the local area around the structure and also to the entire channel system, thus having far-reaching, positive impacts.

This solution is an alternative to lowering the line: it is more cost-effective, and the construction will result in less overall disturbance.